Efficiency is the backbone of successful logistics and warehousing operations. As businesses grow and customer expectations rise, the demand for smarter, more adaptable material handling systems becomes essential. One key innovation helping companies meet these demands is the motorized flexible conveyor—a tool that merges mobility with automation for maximum productivity.

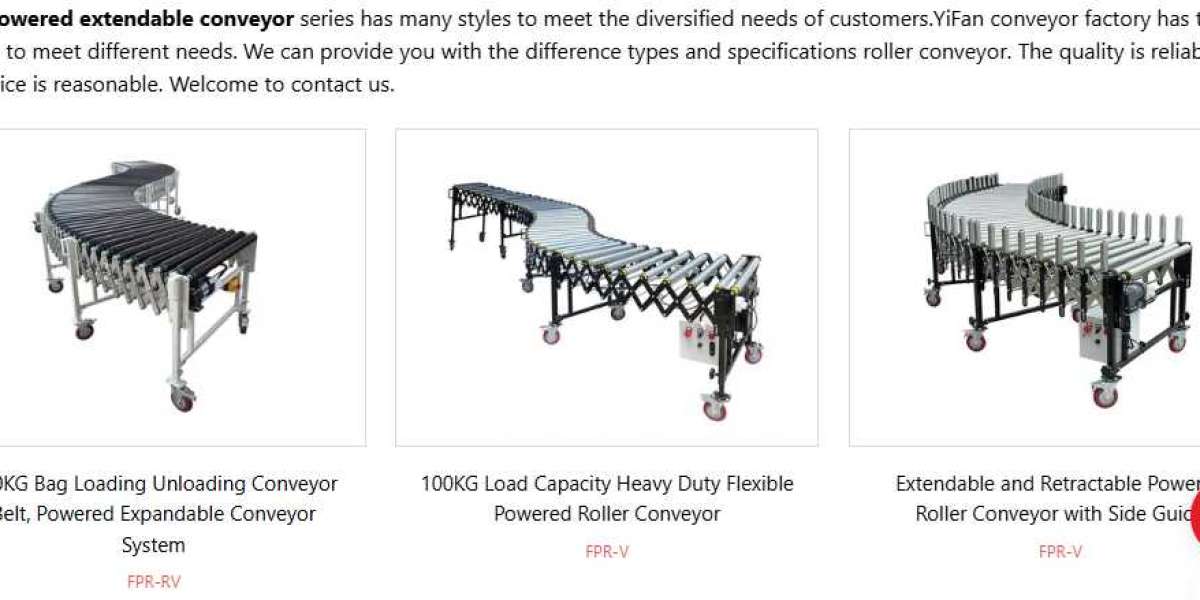

Motorized flexible conveyors are uniquely designed to handle high volumes of goods with minimal human intervention. Unlike traditional conveyor systems, these units can expand, contract, and curve to match the layout of a facility or to navigate around obstacles. This flexibility makes them particularly valuable in dynamic environments like shipping docks, warehouse floors, and e-commerce fulfillment centers.

One of the major benefits of using a motorized flexible conveyor is its role in container loading and unloading. These systems are engineered to adjust their length and configuration, making it easy to reach deep into trucks or containers without requiring additional equipment or manual handling. The motorized rollers power goods forward efficiently, reducing the time needed for labor-intensive loading processes and increasing overall throughput.

Ningbo YiFan Conveyor Equipment Co., Ltd. has been at the forefront of designing and manufacturing such systems. Since 2016, the company has provided one-stop conveyor solutions tailored to a range of industries including health and beauty, automotive, home appliances, and optical equipment. Backed by a strong technical RD team, YiFan ensures that each conveyor is built for durability, ease of use, and maximum performance.

Motorized flexible conveyors are more than just machinery—they're a transformative asset for companies aiming to stay competitive in today’s fast-paced market. By integrating these solutions into their workflow, businesses can reduce manual labor, enhance worker safety, and ultimately deliver better service to their customers.