The global Low-Free Formaldehyde UF Resin market is experiencing robust expansion as industries increasingly adopt eco-friendly and low-emission chemical solutions. Valued at USD 945.6 million in 2024, the market is projected to grow at a CAGR of 5.9%, reaching USD 1.59 billion by 2032. This strong outlook is supported by stringent environmental regulations, rising sustainability initiatives, and growing applications across wood adhesives, furniture manufacturing, and engineered wood panels.

Get Sample Report of Low-Free Formaldehyde UF Resin Market @ https://marketintelo.com/request-sample/5921

Market Overview

Low-free formaldehyde UF resins have gained substantial traction in recent years due to increasing global awareness regarding indoor air quality and emission standards. These resins contain significantly lower levels of free formaldehyde compared to conventional urea-formaldehyde resins, making them ideal for use in products such as particleboard, MDF, plywood, and laminates. As industries prioritize eco-friendly materials without compromising performance, low-free formaldehyde UF resins are becoming a key component in sustainable manufacturing practices.

Key Market Drivers

The strong adoption of low-emission wood adhesives across residential, commercial, and institutional construction sectors is a major driver propelling market growth. Governments worldwide have implemented stricter regulations to reduce formaldehyde emissions from furniture, building materials, and interior products. As a result, manufacturers are increasingly shifting toward low-free formaldehyde UF resins to meet compliance standards such as CARB Phase II, EPA TSCA Title VI, and various European E1/E0 emission ratings.

In addition to regulatory pressure, consumer preferences are increasingly favoring sustainable materials with minimal VOC emissions. This shift has influenced furniture manufacturers, interior designers, and developers to integrate greener alternatives across their supply chains. Furthermore, advancements in resin chemistry and production technologies have enhanced the bonding strength, durability, and moisture resistance of low-free formaldehyde UF resins, making them suitable for a wider range of applications.

Another notable driver is the booming global furniture and construction industries, particularly in emerging economies. Rising urbanization, infrastructure development, and increased spending on residential and commercial interiors are contributing significantly to market demand.

Get Sample Report of Low-Free Formaldehyde UF Resin Market @ https://marketintelo.com/request-sample/5921

Market Segmentation Insights

The Low-Free Formaldehyde UF Resin market is segmented by type, application, and end-use industry. Key types include ultra-low formaldehyde resins and near-zero formaldehyde resins, both of which cater to industries with rigorous emission requirements. Applications primarily span particleboards, MDF, plywood, laminated boards, and molded products.

Among all applications, particleboard and MDF segments hold the largest shares due to their extensive use in furniture, flooring, and interior décor products. In the end-use landscape, the furniture manufacturing sector leads the market, followed closely by the building and construction industry. Increasing demand for engineered wood panels in modular homes, office spaces, and retail structures has further strengthened market expansion.

Regional Analysis

North America remains a significant market for low-free formaldehyde UF resins as the region enforces some of the strictest emission regulations globally. The United States, in particular, continues to experience high adoption rates driven by the furniture industry's transition toward safe and sustainable materials.

Europe follows closely, with Germany, Italy, and France leading the way in implementing formaldehyde-free material initiatives. The region's strong manufacturing base, combined with consumer awareness around environmental health, supports steady market growth.

Asia-Pacific is the fastest-growing region, fueled by rapid industrialization, booming construction activity, and rising demand for cost-effective yet eco-friendly wood adhesives. China, India, Vietnam, and Indonesia are major contributors, driven by their thriving furniture manufacturing sectors and increasing compliance with global environmental standards.

Latin America and the Middle East are emerging markets where rising disposable incomes and growing interest in sustainable building materials are creating new opportunities for low-free formaldehyde UF resin manufacturers.

Read Full Research Study: https://marketintelo.com/report/low-free-formaldehyde-uf-resin-market

Competitive Landscape

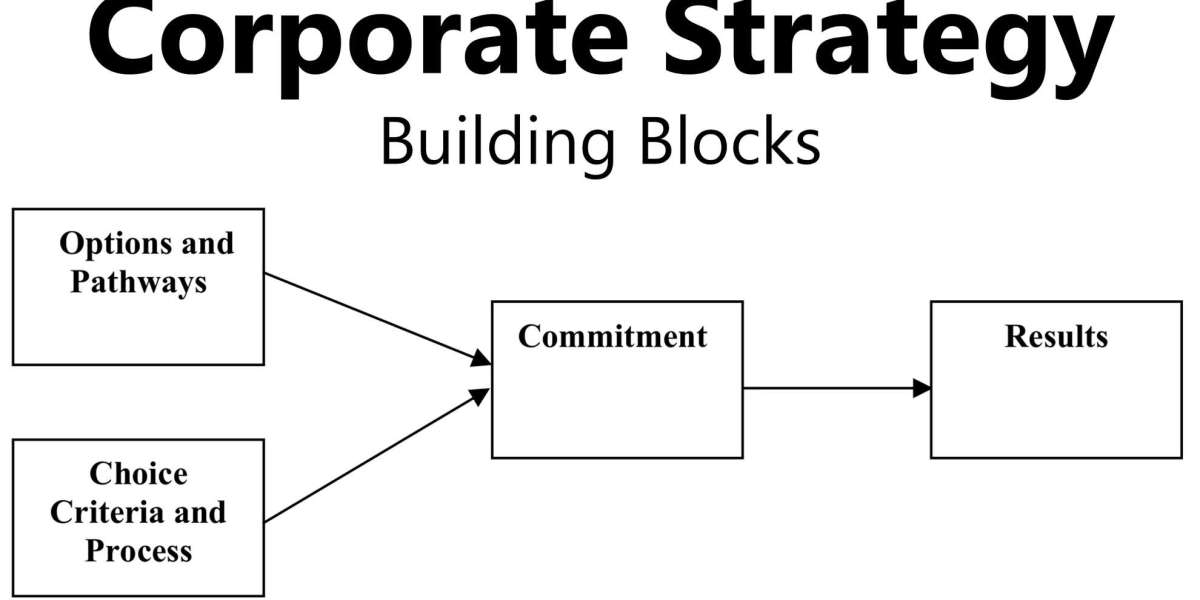

The Low-Free Formaldehyde UF Resin market is characterized by strong competition among leading chemical manufacturers who are investing heavily in RD to develop advanced, low-emission resin formulations. Companies are focusing on improving product performance while maintaining cost efficiency to meet the expanding needs of furniture and construction industries.

Major players in the market include Hexion Inc., BASF SE, Georgia-Pacific Chemicals, Arclin Inc., Kronospan, Dynea AS, and AkzoNobel Specialty Chemicals. These companies are actively enhancing their sustainable product portfolios, expanding manufacturing capacities, and engaging in collaborations with wood panel producers to strengthen their market presence.

Innovation remains a key strategy, with manufacturers introducing bio-based components, improved polymer architecture, and next-generation additives that reduce free formaldehyde emissions to near-zero levels. Additionally, the shift toward circular economy practices is encouraging companies to optimize production processes and reduce environmental footprints.

Future Outlook

The future of the Low-Free Formaldehyde UF Resin market looks highly promising as sustainability continues to shape industrial practices. Growing awareness of indoor air quality, stricter global emission norms, and continuous adoption of eco-friendly materials are expected to sustain market growth throughout the forecast period.

Innovative resin technologies, including hybrid eco-resins and bio-derived adhesives, are likely to gain traction in the coming years. As manufacturers and construction companies embrace green certification programs such as LEED and BREEAM, the demand for low-emission resin solutions will rise even further.

Moreover, as engineered wood products play an increasingly important role in affordable housing, modular construction, and furniture modernization, the demand for low-free formaldehyde UF resins will continue accelerating across global markets.

Conclusion

The Low-Free Formaldehyde UF Resin market is set for steady and long-term growth driven by regulatory compliance, sustainability initiatives, and widespread adoption across furniture and construction industries. With advanced chemistry, improved performance properties, and expanding applications, these resins are becoming integral to the future of eco-conscious manufacturing. Market Intelo’s in-depth research report offers actionable insights, market forecasts, and competitive intelligence to help organizations capitalize on emerging trends and opportunities in this dynamic sector.

Related Report