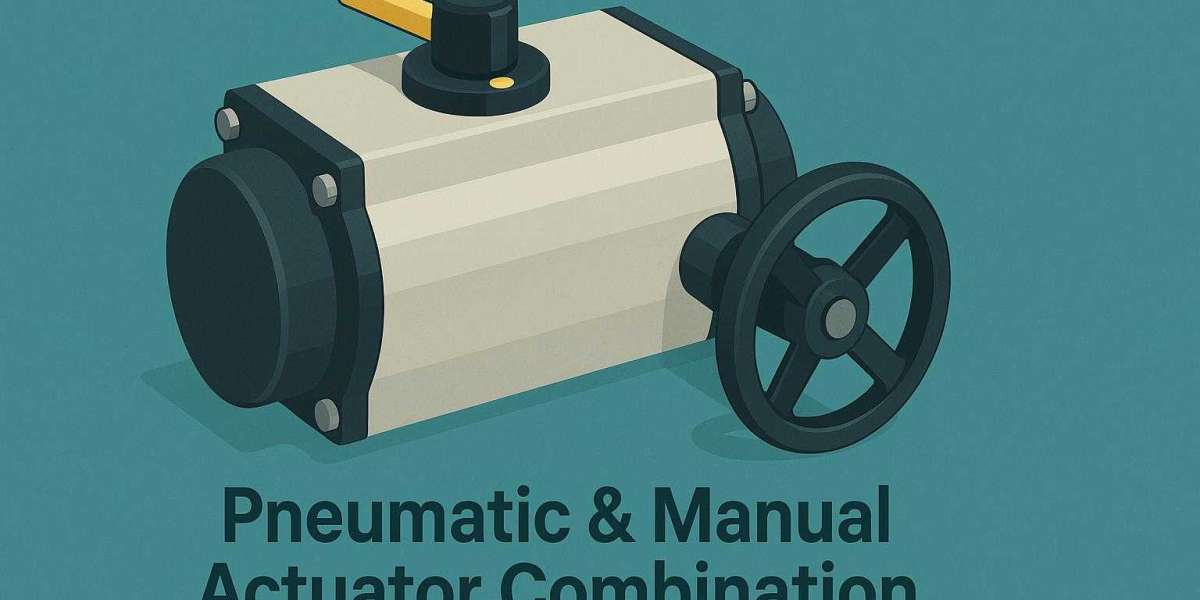

System redundancy is a key principle in industrial engineering, ensuring that operations continue even when one part of the system fails. One component that directly supports this redundancy is the pneumatic/manual actuator combination—a dual-function solution that provides both automated and manual control of valves and mechanical systems.

Pneumatic actuators, which rely on compressed air, offer rapid, efficient actuation that is ideal for automation in harsh or hazardous environments. However, when pneumatic systems experience failures such as air supply loss or controller malfunctions, having a built-in manual option becomes not just useful, but critical.

A pneumatic/manual actuator combination integrates a manual override directly into the pneumatic actuator design. This allows operators to bypass automation and maintain control of the process manually, without needing additional tools or modifying the system. In environments where safety and uptime are top priorities, this combination ensures that control is always available.

This dual capability is particularly advantageous during system startup, shutdown, or maintenance. Operators can test valve function manually, isolate sections for inspection, or perform emergency operations quickly. It also reduces downtime, as there is no need to swap out or add manual control hardware in the event of an automation failure.

Another benefit is system simplicity. Instead of installing separate manual and pneumatic actuators or complex switching setups, a combo actuator consolidates functionality in one compact unit. This reduces space usage, wiring, and maintenance overhead, making it a cost-effective choice over the long term.

Industries such as water treatment, oil refining, and pharmaceuticals value these actuators for their contribution to both efficiency and safety. They provide reliable, immediate control no matter the situation, enhancing system redundancy and preparedness.

In a world where operational continuity is non-negotiable, the pneumatic/manual actuator combination represents a smart and proactive approach to industrial automation and control.